One facet of every sideloader that is often overlooked, located inside every cab and full of important information, is the sideloader ratings plate.

This post explains the information you will find on each ratings plate.

Sideloader Ratings Plate

This discrete metal panel provides vital information about the sideloader, such as its year of build, weight, attachments, load capacity and load centre. Becoming familiar with the details will not only help you identify what your machine can and can’t do, but it will also help ensure safe usage.

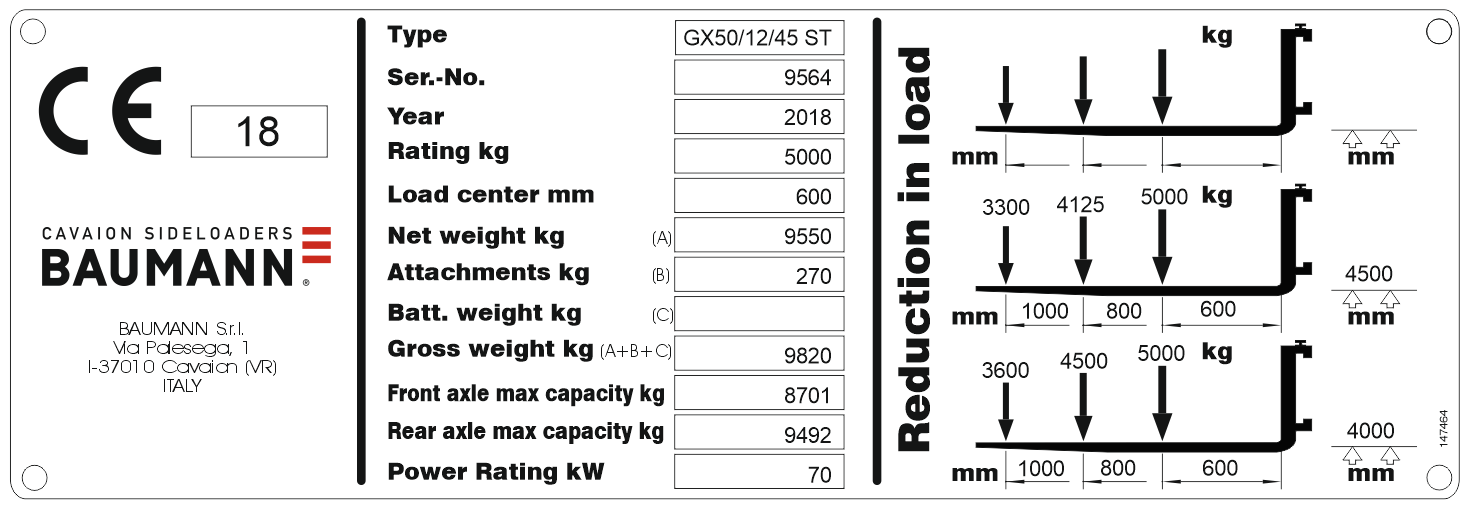

This is what a sideloader ratings plate will look like:

The Basics

The type, serial number and year of manufacturer can tell you a great deal about a Baumann sideloader.

The type will typically be written in a format such as EGX 60 / 14 / 40 ST.

This tells you that the model is from our EGX range, has 6,000 Kgs capacity, a 1400mm bed width and 4,000mm standard mast.

If modifications have been made, such as the addition of an attachment, this can reduce the lifting capacity, in which case the model may appear as EGX 60.50 / 14.12 / 40 TR. Here the nominal capacity (60) is followed by the reduced capacity (.50), whilst the extra width of the attachment has reduced the deck width (14) by 200mm (.12).

The TR indicates the mast is now in a triplex format.

The year of manufacture will help guide you with a warranty or other service-related matters, whilst the serial can be used with our Baumann Online system to identify parts or technical schematics.

Load Centres

The load centre of the truck is used to calculate how far forward from the mast the centre of gravity of a load is, to help specify the lifting capacity at that point. The same load placed further out will require more counterweight to safely lift it (think heavy weights carried at arm’s length, as opposed to close to the body) so understanding how far out the load can be raised is important when considering the truck’s overall capacity both outwards and upwards (at height).

To demonstrate how this changes with distance, a diagram is added to indicate the change in load capacity and different load centres. In our example, the 5,000Kgs capacity of a 4,500mm mast is derated to 4,125Kgs at 800mm load centre, and 3,300mm at 1,000mm. At four metres in height, the load requires less counterweight in comparison, so the amount of deration is reduced.

Sideloader Weights

It’s always handy to know the weight of a machine, particularly when transporting it or operating on certain surfaces, and weight has an important knock-on impact in other ways.

The battery in an electric sideloader forms part of the counterweight, and many calculations are considered when developing the chassis to understand how it will be distributed. More weight means more stability and greater capacity, but too much will affect battery shift life and manoeuvrability.

Creating a smaller, lightweight chassis for the ELX involved designing a series of angled sections to provide stiffness and stability, without excess weight – 2.5 tonnes lower than a conventional engine machine. A new steering axle was developed with extra weight added, providing a lower centre of gravity.

The huge saving in weight allows a larger, intelligent battery system, created specifically for Baumann in a bespoke arrangement. This in turn is supplemented by a new AC wiring schematic, featuring individual cables directly connected to each component to provide maximum efficiency.

The cables themselves were chosen for their mechanical integrity and are typically designed to withstand the harsh environments of aerospace, automotive and energy applications.

The Axle Problem

Two weights for the maximum front and rear axle capacities are also on the ratings plate. At times, this has been wrongly confused with the truck’s maximum capacity, but this fails to take into account the weight of the truck itself.

Safety is the primary reason for manufacturers to place a limit on how much weight each axle can carry. The true purpose of the maximum axle weight is related to restrictions on road use and should never be used as a guide to the maximum truck capacity. It’s also not the case that each axle will support exactly half the truck’s weight and load.

Sideloader Ratings Plate Power Rating

The power rating of an electric truck is fairly straightforward, as all drive motors are rating in kW, but for engine trucks, many of us still refer to horse power of some kind!

Kilowatts or kW is the EU’s standard of measurement. A kilowatt of engine power equates to around 1.34BHP (BHP measures the power from the engine after other loads have been used – like the gearbox and alternator etc. This differs to traditional HP which is the total engine output measured at the flywheel.). The assumption is, more power equates to more torque, the turning power of the engine or how hard it can push you forward.

Whilst this is generally true, a comparison of Baumann engine and electric sideloaders demonstrates that by using electric motors with lower kW motors it is still possible to match, and even exceed, engine-like performance.

Discover The Benefits of Baumann Sideloaders For Yourself

Electrical efficiency is one of many brilliant features designed and developed for Baumann sideloaders. Get in touch with us to discover more features or talk about buying a new or used sideloader.